.gif)

|

Anping Tianshan Wire Mesh Co., Ltd.

|

Gold Index: 65821

You are here: home > INSECT SCREENS ( WINDOW SCREENS ) > FIBERGLASS INSECT SCREENS > Coated plastic fiberglass window screen

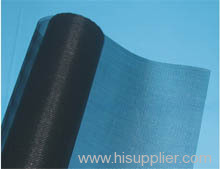

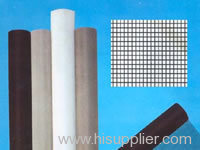

Coated plastic fiberglass window screen

| Price: | 1.0~2.0 USD |

| Payment Terms: | T/T ,L /C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Means of Transport:

by sea ,by air

Packing:

as your require

Brand Name:

Tianshan

material:

fiberglass

Production Capacity:

10,000 square meter per wee...

Delivery Date:

in 15 days

Width:

as your request

package:

standard export package or ...

It is usually rust -resistant ,corrosion -resistant ,doesn't shrink or stretch and so on .These properties makes it a popular window screens

Coated plastic fiberglass window screening is made of glass fiber by the means of single filament plastic coating process, plain weaving and thermal finalizing.

It has the following execellent properties

* Excellent Ventilation

* Sunshade

* Ultraviolet Radiation Proof

* Corrosion Resistance

* Resistance to Burn

* Easily cleaning

* Stable Shape

* Straight in Handle

* Long Service Life

Application:

Coated Plastic Fiberglass Window Screening is the best protective product to keep out a wide range of pests and insects. It is widely used for air exchange and insects proof in high-grade office building, residence and various buildings. It is also for field, garden, vegetable shed, etc.

Specification:

Density(Counts/25MM)|Yarn Diameter|Composition|Woven Structure|Tensile Strength(N/25MM)|

Warp | Weft | (MM) | | Warp | Weft |

18±0.5 | 16±0.5 | 0.28 | PVC 68% |Fiberglass 32% | Plain | 180 | 160 |

18±0.5 | 14±0.5 | 0.28 | PVC 68% |Fiberglass 32% | Plain | 180 | 150 |

Packing and Storage

Packing:

Width(cm): 61, 71, 76, 81, 91, 100, 122, 152, 183, 200, 220

Length(m): 30, 50

Each rollof Coated Pladtic Fiberglass Windoe Screening is wound on a paper

tube, urapped in a plastic bag, then to be packed in carton box

Storage:

Store in cool and dry location, the best condition for storage is under a

temperature between 15 and 35, and at a relative humidity between 35 and 65.

Store out of direct sunlight

Protect rolls from weather and other damage

It has the following execellent properties

* Excellent Ventilation

* Sunshade

* Ultraviolet Radiation Proof

* Corrosion Resistance

* Resistance to Burn

* Easily cleaning

* Stable Shape

* Straight in Handle

* Long Service Life

Application:

Coated Plastic Fiberglass Window Screening is the best protective product to keep out a wide range of pests and insects. It is widely used for air exchange and insects proof in high-grade office building, residence and various buildings. It is also for field, garden, vegetable shed, etc.

Specification:

Density(Counts/25MM)|Yarn Diameter|Composition|Woven Structure|Tensile Strength(N/25MM)|

Warp | Weft | (MM) | | Warp | Weft |

18±0.5 | 16±0.5 | 0.28 | PVC 68% |Fiberglass 32% | Plain | 180 | 160 |

18±0.5 | 14±0.5 | 0.28 | PVC 68% |Fiberglass 32% | Plain | 180 | 150 |

Packing and Storage

Packing:

Width(cm): 61, 71, 76, 81, 91, 100, 122, 152, 183, 200, 220

Length(m): 30, 50

Each rollof Coated Pladtic Fiberglass Windoe Screening is wound on a paper

tube, urapped in a plastic bag, then to be packed in carton box

Storage:

Store in cool and dry location, the best condition for storage is under a

temperature between 15 and 35, and at a relative humidity between 35 and 65.

Store out of direct sunlight

Protect rolls from weather and other damage

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Fiberglass Window Screen

Fiberglass Screen Window

Black Fiberglass Window Screen

Plastic Window Screen

Plastic Insect Window Screen

Plastic Window Screen Netting

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Anping Tianshan Wire Mesh Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Hengshui

Province/State: Hebei

Country/Region: China (Mainland)

You May Like:

Product (783)

- Encryption Products (1)

-

WEDGE WIRE SCREENS ( TYPE )

(180)

-

JOHNSON SCREENS ( MATERIAL )

(114)

-

STAINLESS STEEL WIRE MESHES

(98)

-

INSECT SCREENS ( WINDOW SCREENS )

(155)

-

WELDED WIRE MESHES

(56)

-

METAL WIRES

(8)

-

HEXAGONAL WIRE NETTINGS

(28)

-

CHAIN LINK FENCES

(13)

-

FENCES

(34)

-

PERFORATED METAL MESHES

(6)

-

EXPANDED METAL MESHES

(5)

-

BARBED WIRES

(27)

- FILTER ELEMENTS (15)

- CRIMPED WIRE MESHES (2)

- BLACK WIRE CLOTHES (26)

- CONVEYOR WIRE BELTS (3)

- MINE SCREENS (11)

-

DECORATIVE WIRE MESHES

(1)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)