.gif)

|

Anping Tianshan Wire Mesh Co., Ltd.

|

Anping Tortoise Shell Mesh

| Price: | 5.0~25.0 USD |

| Payment Terms: | T/T;L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Anping Tortoise Shell Mesh

metal welded wire meshes

steel wire mesh

Tortoise Shell Mesh

Metal Tortoise Shell Meshes

Tortoise Shell Mesh

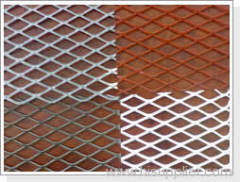

Introduction: it's our newly developed tortoise shell mesh with big mud claws, which is widely applied as fixing of lining of heat resistant material. It is made of carbon steel (A3F), or 0Cr13 for special occasions. Operation procedure is: to tack up the mesh by welding to the inner wall of boiler or hot wind pipes, then to smear heat-resistant materials.

Advantages: it's has a hexagonal meshes and large mud claws, to help fixing the adhersion with heat-resistant materials, preventing peeling or fall off.

Application: to help fixing lining materials.

Materials: A type carbon steel 0Cr13.1Cr13..0Cr18Ni9.1Cr18Ni9Ti, with mesh spacing 2cm-6cm, thickness 1cm-2.5cm, thickness 1mm-3mm.

tortoise shell mesh

Netting Sizes: We can make mesh nettings upon customers' requirements. We have made dozens of sizes of parts for OEMs, including large petroleum chemical mechanism, special for catalyzering device. It has excellent performance of anti-abrasion and strength. Anti-abrasion lining is fixed with tortoise shell meshes of A3F carbon steel, such as reactor and Class I or II whirlwind separator, and U-shaped regenerator pipes, some parts are supported with tortoise shell meshes made of alloy 1Cr13, such as regenerator, Class I or II whirlwind separator. Tortoise shell meshes are made by perforating flat steel belt of 20*17.5mm and fixing them to a board.w material,th Tortoise Shell Meshes

Our newly developed tortoise shell mesh have big mud claws, which is widely applied as fixing of lining of heat resistant material. It is made of carbon steel (A3F), or 0Cr13 for special occasions. Operation procedure is: to tack up the mesh by welding to the inner wall of boiler or hot wind pipes, then to smear heat-resistant materials.

Tortoise Shell Mesh has gotten extensive application in chemical industry,petroleum,power generation,etc.It appears good performance ,it is a hexagonal hole mesh ,with bar steel pressed and punched,three are small holes in every border for interflowing between the holes .Tortoise Shell Meshes is welded on cyclone dust collector or on the inside wall of the cylinder,poured refractory material.So ,it has prolonged lifetime.

For large petrochemical installations, in particular, it helps catalyst for major equipment installations of the lining of the main structural components, it can improve the wear resistance and lining strength, abrasion resistance, are used shells network reinforcement, the general location using carbon steel (A3F) shells network, and as a reactor, 2 Cyclone and the U-regenerator, flue pipe installed, high temperature alloy parts (1Cr13) shells network, and as a regenerator, two cyclone and other places. Shell network of 20 * 17.5 mm of flat steel with Chong% of the hexagonal lattice, fixed-nail in the insulation board.

Materials of Tortoise Shell Meshes

Carbon steel 0Cr13.1Cr13..0Cr18Ni9.1Cr18Ni9Ti, with mesh spacing 2cm-6cm, thickness 1cm-2.5cm, thickness 1mm-3mm.

Netting Sizes of Tortoise Shell Meshes

We can make Tortoise Shell Meshes upon customers' requirements. We have made dozens of sizes of parts for OEMs, including large petroleum chemical mechanism, special for catalyzering device. It has excellent performance of anti-abrasion and strength. Anti-abrasion lining is fixed with tortoise shell meshes of A3F carbon steel, such as reactor and Class I or II whirlwind separator, and U-shaped regenerator pipes, some parts are supported with tortoise shell meshes made of alloy 1Cr13, such as regenerator, Class I or II whirlwind separator. Tortoise shell meshes are made by perforating flat steel belt of 20*17.5mm and fixing them to a board.

Advantages of Tortoise Shell Meshes:

it's has a hexagonal meshes and large mud claws, to help fixing the adhersion with heat-resistant materials, preventing peeling or fall off.e weld

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Tortoise Shell Mesh

Tortoise Shell

Anping Hexagonal Wire Mesh

Anping Wire

Shell

Anping Wire Meshes

More>>